A European Project for Highest Efficiencies in Concentrating Photovoltaics

The EU-funded project Concentrating Photovoltaic modules using advanced technologies and cells for highest efficiencies (CPVMatch) will bring practical performance of high concentrating photovoltaics (HCPV) closer to theoretical limits. Leading European experts in their respective fields of science, technology and industrialization are engaged in the project to realize novel multi-junction solar cell architectures and innovative HCPV module concepts.

The EU-funded project Concentrating Photovoltaic modules using advanced technologies and cells for highest efficiencies (CPVMatch) will bring practical performance of high concentrating photovoltaics (HCPV) closer to theoretical limits. Leading European experts in their respective fields of science, technology and industrialization are engaged in the project to realize novel multi-junction solar cell architectures and innovative HCPV module concepts.

CONCEPT

It has been proven that the only realistic path to close the gap between theoretical and practical ultra-high efficiency solar cells is the monolithic multi-junction (MJ) approach, i.e. to stack different materials on top of each other. Each material/sub solar cell converts a specific part of the sun' spectrum and thus manages the photons properly. However, large area multi-junction cells are too expensive if applied in standard PV modules. A viable solution to solve the cost issue is to use tiny solar cells in combination with optical concentrating technology, in particular, HCPV, in which the light is concentrated over the solar cells more than 500 times. The combination of ultra-high efficient cells and optical concentration lead to low cost on system level and eventually to low levelised electricity costs, today well below 8 €cent/kWh and at the end of this project below 5 €cent/kWh. Therefore, to achieve an optimised PV system (high efficiency, low cost and low environmental impact), world-wide well-known partners in the field of CPV technology work together in this project to run and progress together the development of highly-efficient multi junction solar cells and the improvement of the CPV module technique.

IMPLEMENTATION AND OBJECTIVES

The collaborative project started in May 2015 with a duration of three and a half years and an EC contribution of 4.95 M€. The consortium consists of four research institutions (Fraunhofer ISE, RSE, CEA, Tecnalia), one University (UPM), two industry partners (AZUR Space Solar Power, AIXTRON) and two SMEs (ASSE, Cycleco) and is coordinated by Fraunhofer ISE. The consortium addresses in their research all topics required to manufacture highly efficient CPV modules. This includes material issues, manufacturing and equipment aspects and production challenges. University and research institutes are working in close cooperation with industry partners in order to ensure fast industrial exploitation of all results within the whole value chain.

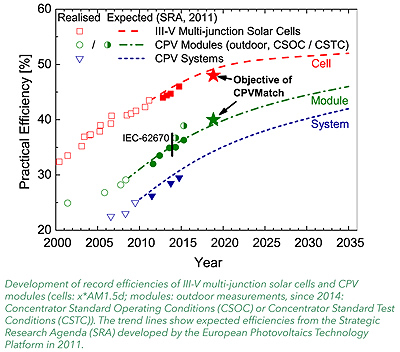

The central objective of CPVMatch is to realise HCPV solar cells and modules working at a concentration level ≥ 800x with an efficiency of 48 % and 40 %, respectively, with a low environmental impact.

In order to develop the targeted high performing CPV solar cells and modules, two strategies are adhered to (both for the multi-junction solar cell and module technology). The work on cells and module technologies is accompanied by a profound lifecycle and environmental assessment and the development of adapted characterization methods of new multijunction cells and HCPV modules. The following specific objectives have been defined for the project:

- - Development of a novel wafer bonded four-junction solar cell for better spectral matching with an efficiency of 48% using advanced materials and processes

- - Development of a lattice-matched multi-junction solar cell with high efficiency potential and low process cost, comprising nanostructured coatings and innovative lattice matched materials, obtained by combing III-V and IV elements

- - Development of innovative, Fresnel lens-based HCPV modules

- - Development of smart, mirror-based HCPV modules

- - Life-cycle and environmental assessment of new multi-junction cells and HCPV modules

- - Assess the developments realized on solar cells and modules by means of adapted characterization methods

IMPACT

The central expected impact of this project is to significantly increase the technical performance of III-V multi-junction solar cells and HCPV modules and thus to lower the cost for PV energy. HCPV systems reach efficiency levels which flat-plate PV will never be able to reach cost-efficiently. In addition, CPVMatch will help to increase the reliability, maintainability, and lifetime of CPV while increasing simplicity and decreasing operation and maintenance costs.

One of the central aims of the project is also to reduce the life-cycle environmental impact of electricity generation. HCPV systems already have low energy payback times of 6 to 9 months in Southern Europe, which will be further reduced through CPVMatch. Therefore, this project will contribute to solving the global climate and energy challenge by improving one of the most promising solar energy technologies.

CPV power plants in Southern Europe could deliver predictable, low-cost and reliable electricity and hence improve EU energy security by lowering the need for energy imports of fossil fuels and nuclear material. This holds in particular as most of the CPV manufacturing value chain lies within Europe and includes several of the key enabling technologies, which were identified as essential for maintaining European competitiveness. Many start-up and smaller companies exist in Europe that can produce CPV systems, including cells, modules and other system components. Hence the success of this project will help to nurture the development of the European industrial capacity to produce CPV components and systems and to open new opportunities for companies and the strong research community in Europe.

Contact details:

Project Coordinator

Dr. Simon P. Philipps, Fraunhofer ISE

Dr. Andreas W. Bett, Fraunhofer ISE

Email: cpvmatch@ise.fraunhofer.de

Website: www.cpvmatch.eu

This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 640873. The authors are solely responsible for this information and it only reflects the author's view. The European Commission or any of their agencies are not responsible for any use that may be made of the information it contains.