New Environmental friendly and Durable conCrete, integrating industrial by-products and hybrid

systems, for civil, industrial and offshore applications.

MAIN GOAL

By integrating industrial by-products and hybrid systems,

EnDurCrete will develop a new environmentally-friendly

and durable concrete for harsh environmental

applications using new types of eco-friendly Portland

composite cements.

Concrete based on ordinary Portland cement has been

for many years the principal structural material for

building durable construction. Current state-of-the-art

concrete types based on Portland cement with very high

substitution by supplementary cementitious materials

tend to fall behind in terms of performance and durability,

which is particularly critical when applied in harsh

environmental conditions. Moreover, cement production

process is responisbile itself of almost ten percent of the

worlds’s man made CO2 emission. Therefore, projects

aimed at improving formulations and production methods

to reduce CO2 emissions, energy demand and material

consumption from cement and concrete manufacturing

represent key topics on the agenda of both the European

construction industry and the European Commission. One

of such projects is the EnDurCrete project sponsored by

the EU Research and Innovation Programme Horizon 2020

and led by HeidelbergCement AG.

The EnDurCrete project aims to develop a new cost efficient,

sustainable reinforced concrete for long-lasting

and added-value applications. The concept is based on

the integration of novel and optimised low-clinker cement,

new nano- and micro-technologies and hybrid systems

ensuring enhanced durability of concrete structures

with high mechanical properties, self-healing and selfmonitoring

capacities.

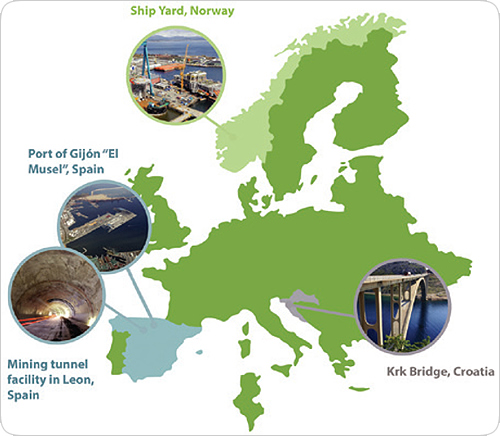

Project demo sites where technology applications

will be tested

The EnDurCrete project involves 16 European partners,

including industry leaders in the fields of cement and

concrete production, construction companies, chemical

admixture producers, universities and technological

research institutes as well as service providers. The

research faces several topics, from the development of

new ecological low-clinker cements, innovative corrosion

inhibitors, conductive fillers/fibers enhancing self-sensing

capabilities of concrete, special reinforcement and selfhealing

solutions to the testing of durability in laboratory

and on large-scale demonstrations in real environment

conditions. Data collected during the testing will be

further used as an input for the modelling of concrete

performance and development of service life prediction

models. Furthermore, the knowledge and experience

gathered by the project is supporting the preparation of

novel standards for more eco-friendly cements

and concretes.

Following the concrete development stage, full-scale

demonstrators will be cast and placed in working sites of

tunnels, ports, bridges and offshore structures, to prove

the enhanced durability and the improved long-term cost

efficiency of the new concrete structures in such critical

applications. However, EnDurCrete is not only about

developing concrete but also about pushing forward test

methods and analysis tools. Advanced non-destructive

continuous monitoring and testing tools and procedures

will be developed and used, including technologies tuned

for providing concrete with self-sensing capabilities. They

are intended to complement the conventional durability

testing procedures in laboratories.

Project ID: 760639

Website: www.endurcrete.eu

Video: www.youtube.com/watch?v=Jfgom15vUsg

Start date: January 2018

Duration: 42 months

Project coordinator: Arnaud Muller

Contact email: arnaud.muller@heidelbergcement.com