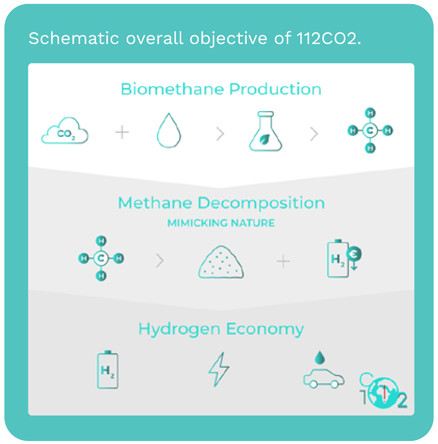

Methane decomposition (MD)

reaction, also known as methane

pyrolysis, allows the conversion

of methane from natural gas or

biomethane into solid carbon and

hydrogen with high purity:

CH4 → C (s) + 2H2 ΔH0 = 75.3 kJ mol-1

This reaction has the unique feature

of being 100% selective. Apart from

allowing the swift decarbonization

of the energy, when biomethane is

used, this reaction has the power to

remove CO2 from the atmosphere

as it produces H2 at very competitive

costs. This technology enables

using the present storage and

distribution infrastructure for

natural gas and produces H2 to be

used locally as a fuel for electricity/

heat or as feedstock for chemical

industries (steel production, ammonia

synthesis, reversal petrochemistry,

etc.).

Considering only the price of the raw

materials, H2 from the decomposition

of natural gas costs 1.9 €/kg, while

biomethane-derived H2 costs 2.2

€/kg. At the present prices of CO2

allowances, >60 €/ton, this process

saves 0.54 €/kg of H2. The MD of

biomethane removes CO2 from the

atmosphere. Assuming a cost for the

direct air capture of CO2 of 150 €/ton

and for its sequestration of 50/ton,

per 1 kg of H2 produced, 0.60 € are

saved in capture and sequestration

of CO2.

The industrialization of catalytic MD

has been hindered so far by the

extremely fast catalyst deactivation,

which is caused by the inevitable

coverage of catalytic sites by the

formed solid carbon. Competing

institutions/companies are developing

high temperatures MD processes

involving either metal liquid reactors

or reactors using carbon catalyst

particles; however, these approaches

are energy-intensive, dangerous to

operate and display low catalytic

activity.

112CO2, a FET-Proactive project,

aims at developing a disruptive low

temperature (ca. 550 °C) methane

decomposition process, using

abundant and cheap metallic

catalysts. Briefly, the designed

reactor uses Ni-based catalysts,

which are very active but need to be

cyclically regenerated. It is expected

to reach >0.45 gH2 gCat

-1 h-1 and

stable for at least 10 000 h.

112CO2, a FET-Proactive project,

aims at developing a disruptive low

temperature (ca. 550 °C) methane

decomposition process, using

abundant and cheap metallic

catalysts. Briefly, the designed

reactor uses Ni-based catalysts,

which are very active but need to be

cyclically regenerated. It is expected

to reach >0.45 gH2 gCat

-1 h-1 and

stable for at least 10 000 h.

The project, which has started in

September 2020, gathers some of

the finest EU research laboratories

and companies, including University

of Porto, author of this new MD

concept; Pixel Voltaic Lda., which

is a spin-off company from UPorto,

responsible for designing the process

lab prototype; CSIC to synthetize

the catalysts; DLR to develop proton

conducting ceramics for efficient and

cost-effective H2 purification; EPFL

responsible for the dissemination

activities; Paul Wurth S.A. and Quantis

for performing life cycle assessment

and economic analysis.

As explained by Adélio Mendes,

professor at the University of Porto

and project coordinator: "preliminary

results allowed to reach a maximum

catalytic activity of 3 gH2 gCat

-1 h-1 and

proved that the cyclic regeneration

allows keeping the catalyst at its

maximum catalytic activity. Initial

experiments demonstrated worldrecord

stabilities, using a compact

reactor loaded with commercial

and non-optimized catalysts."

112CO2 also proposes an ambitious

communication strategy, aiming

to involve stakeholders, investors,

researchers, youngsters, and students

for this emergent technology.

112CO2 project has received funding from the European Union's Horizon 2020 research and innovation Programme under the grant agreement No 952219.