Domestic wastewater (WW)

contains thermal energy

in the form of organic

matter (close to 4 kWh/kg

Chemical Oxygen Demand (COD)

for 500 mg COD/l – or about

2 kWh/m3), but in conventional

WW treatment plants (WWTP) the

organic matter is oxidised with an

electricity consumption of at least

0.5 kWh/m3, and producing sludge.

In larger WWTP with capacities above

50,000 population equivalent (PE),

this biomass can be converted to

biogas in anaerobic digestion, but on

average only up to 50% of the energy

can be recovered by co-generation.

Domestic wastewater (WW)

contains thermal energy

in the form of organic

matter (close to 4 kWh/kg

Chemical Oxygen Demand (COD)

for 500 mg COD/l – or about

2 kWh/m3), but in conventional

WW treatment plants (WWTP) the

organic matter is oxidised with an

electricity consumption of at least

0.5 kWh/m3, and producing sludge.

In larger WWTP with capacities above

50,000 population equivalent (PE),

this biomass can be converted to

biogas in anaerobic digestion, but on

average only up to 50% of the energy

can be recovered by co-generation.

Other valuable resources in WW are

nutrients, essential ingredients for

plant growth in agriculture, as each

European produces yearly about

4.5 kg N, close to 1 kg P and 2 kg K.

However, centralised WWTP can only

recover a small fraction of diluted

nutrients by precipitating up to 50% of

the phosphorus in sidestreams, while

two thirds of the nitrogen is converted

to gas and lost to the atmosphere. In

the production of artificial fertilizer,

this nitrogen is gained back from the

atmosphere with an energy input of

10 to 15 kWh/kg.

One approach to increase recovery

rates and optimizing the energy

balance is by treating concentrated

streams in a decentralized concept,

before the waste is diluted by the

freshwater use of 150 l/PE/d. The

project H2020 Run4Life (Recovery

and Utilization of Nutrients 4 Low

Impact Fertiliser) demonstrates the

options of decentralized WWTP,

based on the source-separated

collection of greywater (from

showers, basins…), blackwater, from

toilets), and kitchen waste, with each

flow receiving optimal treatment for

resource recovery.

As part of Run4Life, blackwater from

an office building in Nigran, near

Vigo in Galicia, is treated with the

AnMBR process, combining Anaerobic

Digestion (AD) with membrane

filtration to separate biosolids and

clean water. As ultrafiltration with

pore sizes between 0.04-0.1 μm

retains solids, bacteria and even

some viruses, permeate is suitable

for reuse while providing nutrients for

agriculture (fertigation). This in turn

reduces CO2 emissions by recovering

organic matter and avoiding the need

of mineral fertilizer.

Blackwater treatment at room

temperature removes above 90% of

the organic matter, while biogas with

>75% of methane concentration is

obtained and biosolids production

is cut by half compared to

conventional WWTP. The higher

organic concentration of blackwater

allows for direct AD treatment,

and incorporating the organic

kitchen waste increases biogas

production and nutrient recovery,

while avoiding biowaste collection

and transport.

This concept will also be applied by

Aqualia in the new Life Zero WasteWater project, in collaboration with

the University of Valencia, to exploit

their joint patent (EP3225596).

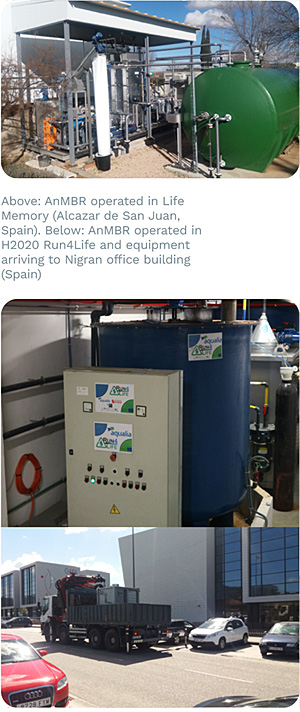

AnMBR has been demonstrated at

different WWTPs, achieving low power

requirements (0.15 kWh per m3 of

treated water in Life Memory) whilst

producing a nutrient-rich, pathogenfree

permeate.

AnMBR has also been used to retrofit

of an old septic tank of a small village

(20 m3/d WW), as OPEX was 20% less

compared to conventional WWTP. A

larger AnMBR to treat domestic WW

from an industrial park (400 m3/d), to

generate bioenergy and reuse water

in the factories and green spaces

is under design as a sewer mining

concept in H2020 Rewaise.

The Run4Life project receives funding from the EU Horizon 2020 Research and Innovation programme, GA no 730285. This article reflects only Aqualia's view. The European Commission is not responsible for any use that may be made of the information it contains.