The European Commission has established clear objectives intended at reducing greenhouse gas emissions and promoting the wider utilisation of renewable energy sources. Geothermal energy holds great potential for contributing to these goals. However, the utilisation of geothermal brines to extract heat presents unique materials and technological challenges, such as corrosion and scaling leading to blockages or plugging, which have a significant impact on various components of a geothermal power plant, including turbines, conduits and well pipes.

The European Commission has established clear objectives intended at reducing greenhouse gas emissions and promoting the wider utilisation of renewable energy sources. Geothermal energy holds great potential for contributing to these goals. However, the utilisation of geothermal brines to extract heat presents unique materials and technological challenges, such as corrosion and scaling leading to blockages or plugging, which have a significant impact on various components of a geothermal power plant, including turbines, conduits and well pipes.

One crucial element within a geothermal power plant is the heat exchanger. In this project, we are pursuing a multi-stage, practical approach to implement specialised coatings for heat exchanger applications. During the coating development phase, we encountered various types of heat exchangers in a geothermal power plant, each with specific thermodynamic requirements crucial for optimising the energy generation cycle. For instance, in condenser heat exchangers, the condensation of liquid films creates a thermal barrier, resulting in energy generation inefficiencies. To address this issue, we explored the use of hydrophobic coatings that prevent the formation of liquid films through droplet condensation. This is just one example of the numerous developments within the GeoHEX project.

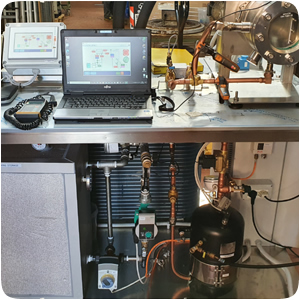

The selection and testing phase of these coatings involved the design and fabrication of instrumented test rigs by one of the consortium partners. These rigs enable us to assess the coatings' effectiveness in mitigating corrosion, preventing scaling, and enhancing energy efficiency. For instance, one of the rigs was deployed inside a geothermal power plant in Iceland, connected to a bypass in the geothermal brine pipeline, to determine which coating could effectively reduce mineral scaling while continuously monitoring thermal efficiency.

During the testing phase within the heat exchangers, it is worth noting that certain parameters are challenging to assess outside of an actual energy generation cycle. Parameters like the impact on sub-cooling or the flow rate at the turbine's exit pose difficulties. One of the Project's objectives was to construct a pilot modular geothermal power plant for testing heat exchangers with and without the novel coatings developed in GeoHEX. The coatings' efficacy was evaluated based on the energy output from a small turbine.

GeoHEX represents a collaborative, cross-border initiative involving partners from seven diverse nations. These include the United Kingdom, with TWI, the University of Leicester, and Technovative Solutions; France, with Enogia and CEA; Romania, with the University of Bucharest; Iceland, with On Power, University of Iceland, ICETEC and Grein Research; Italy, with Spike Renewables; Norway, with Flowphys; and the Philippines, with Quantum Leap JMB. The shared objective among these international collaborators is the development of specialised engineered coatings tailored exclusively for the geothermal sector.