Fibreship will entail an important energy saving reducing by 70% the structural weight of the vessels by means of composite materials.

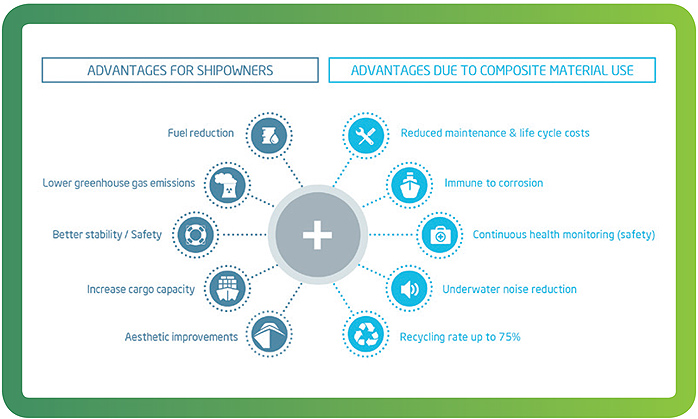

FIBRESHIP (H2020, Grant 723360) is an ambitious R&D project aimed at developing a new market focused on the design and construction of commercial vessels in composite materials (FRP, Fibre-Reinforced Polymers) greater than 500GT (approximately 50m in length). From the energy point of view, this project will imply a significant reduction in energy consumption thanks to the reduction in structural weight of the vessels, among other advantages for shipowners. FIBRESHIP has a overall budget of €11M, being partially supported by the European Commission (EC) within the H2020 research program and it is participated by 18 partners led by TSI S.L.

The main objective of FIBRESHIP project is to generate the regulatory framework for designing and building of large-length ships in FRP materials overcoming the technical challenges identified. In order to achieve this goal, the project is auditing innovative FRP materials for marine applications, elaborating new design guidelines, generating production and inspection methodologies, and developing numerical software tools for assessing the structural performance.

Three vessels categories were targeted as the most promising for market orientation in the framework of FIBRESHIP project: i) lightweight commercial vessels, ii) passenger, transportation and leisure vessels and iii) special service vessels.

Along the first period of the project, the following objectives have been reached:

- A evaluation of impacts and a cost-benefit calculator have been performed for large ships of composite materials.

- A SWOT analysis (Strengths, Weaknesses Opportunities, Threats) focused on all involved marine stakeholders (shipyards, suppliers, shipping principals) was carried out, showing the roadmap of composite adoption in EU Shipping Market.

- Several experimental tests were performed, consisting of mechanical, fatigue and fire performance assessment of composite materials.

- A composite material selection methodology for large vessels was carried out as well as a set of eligible joining techniques.

- A literature review was conducted on the current marine regulatory framework relevant to the use of FRP materials.

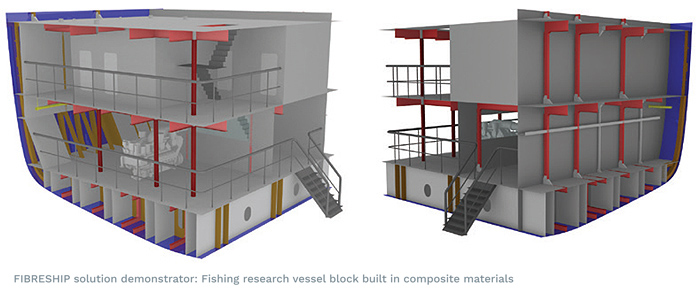

- The design of 3 different vessel in composite material is progressing according to the plan: containership, ROPAX and fishing research vessel.

- A production methodology which meets the needs of composite material shipbuilding of large vessel was conducted to reach a cost-efficient balance, considering modular subdivision and production sequencing recommendations.

- Different strategies regarding inspection, life cycle, structural health monitoring and waste treatment were raised and their assessment is ongoing.

- A software suite made up of different validated coupled numerical models able to simulate the structural behavior was developed.

- Vibro-acoustics tests were performed in a small length vessel of composite material for underwater radiated noise for numerical model validation and on board vibration & noise assessment.

- A full-scale testing campaign in a container ship in harsh sea states is scheduled for April 2019 to obtain useful data to assess the defined structural healdh monitoring strategy.

In order to show the achievements and technological breakthroughs of FIBRESHIP in composite materials vessel design, a full-scale block of a Fishing Research Vessel (FRV) is being built at IXBLUE shipyard. It is scheduled to be finished for the 2nd FIBRESHIP Workshop at the end of June 2019.

Contact details:

Alfonso Jurado, Head of R&D Department TSI and Project Coordinator

Email: alfonso.jurado@tsisl.es

Web: www.fibreship.eu