A Novel Process for the Production of Biofuels Allowing for Net Negative CO2 Emissions

While notable advances towards

a de-carbonization of the energy

sector have been achieved in recent

years, closing the carbon cycle

of the transport sector, which is

responsible for almost one quarter

of the European GHGE emissions2

and consumes 36% of the global

final energy1, still signifies a key

challenge on the way towards a

carbon-neutral society. A major

hurdle standing in the way of this goal

is the substitution of fossil fuels in

heavy freight transport and aviation

industry, where electrification is

currently not a viable option. In light

of current policies and strategies

related to climate protection and

energy transition, implemented in

order to further promote carbonneutral

transport, novel, sustainable,

and yet competitive technologies are

urgently needed.

One auspicious pathway to reduce

greenhouse gas emissions of the

transport sector is the large-scale

roll-out of so-called 2nd generation

biofuels, which are produced from

bio-based residue materials. By

focusing on biological non-foodgrade

precursors, this approach

contributes not only to a sustainable

shifting from fossil to renewable

resources, but also facilitates the

large-scale economic production of

biofuels, without detrimental effects

on food availability and prices arising.

Yet, one key issue generally related

to 2nd generation biofuels is their high

production cost, which make them

uncompetitive in the current fossil

fuel governed market environment.

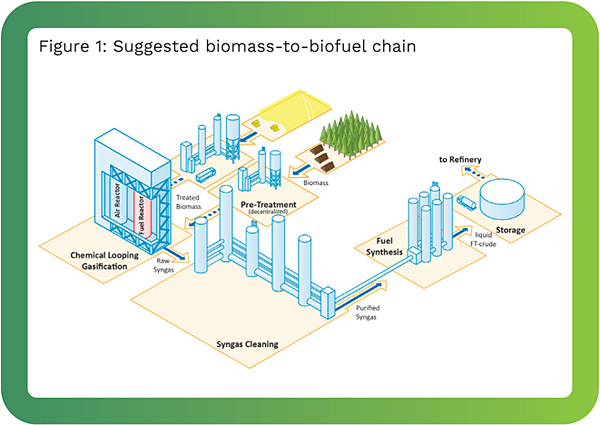

To alleviate this problem, an efficient

technology for the production of

liquid fuels based on chemical

looping gasification (CLG) of biogenic

residues is being developed within

the scope of the EU-funded Horizon

2020 project CLARA3, executed by

thirteen international members

including universities, research

institutes, and industry partners. The

combination of CLG, which does not

rely on costly air separation, with

other novel technologies related

to biomass pre-treatment and gas

cleaning yields a process chain,

allowing for major reductions in

biofuel production costs, so that

final end-product prices as low as

0.7 €/l can be realized. Moreover, the

suggested process chain facilitates

net negative CO2 emissions, as

carbon of biogenic origin can be

captured effi ciently within the

process, before being sequestered

(CCS) or utilized (CCU).

These aspects, in combination

with projected advances in terms

of process scalability, make the

suggested process chain an

auspicious carbon-negative value

chain, promising an efficient decarbonization

of the transport sector,

while at the same time guaranteeing

market compatibility. Within the

scope of the CLARA project, the

entire biomass-to-biofuel process

chain, schematically shown in the

figure above, is to be investigated

in 1 MWth pilot scale, thus further

propelling the novel technologies

towards market maturity in an

industrially relevant environment

Further information:

Website: https://clara-h2020.eu/

1. International Energy Agency, Key World Energy Statistics 2018. OECD, 2018.

2. Transport emissions - A European Strategy for low-emission mobility, https://ec.europa.eu/clima/policies/transport_en.

3. This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 817841.