The photovoltaic (PV) industry is experiencing a crucial moment in its development. With an ever-increasing number of installations, there is an equally growing challenge: the environmental impact of PV waste. In 2020 alone, the global PV industry generated approximately 400,000 tonnes of future waste, and this number is expected to surge to an estimated 5.5 million tonnes annually by 2050.

By then, 60–78 million tonnes of raw materials will be locked up in the end-of-life (EOL) PV modules. Within the European Union, the situation is just as alarming, with 150,000 tonnes of PV waste expected to be produced annually by 2030. This presents an urgent challenge for the industry, one that is further highlighted by the fact that many of the PV systems installed decades ago were never designed with end-of-life management in mind.

The majority of these ageing PV systems were built with little consideration for future disassembly and recycling. As these modules approach the end of their 25-year lifespan, an innovative solution is required to recover the raw materials they contain, from silicon to critical metals. Current recycling methods are far from sufficient.

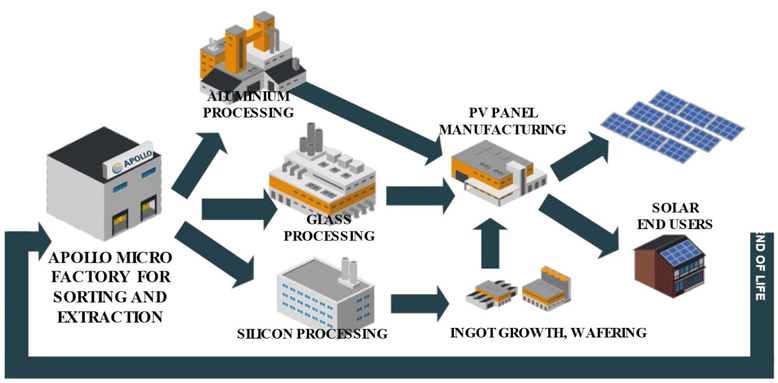

Traditional recycling processes for crystalline silicon modules focus on recovering only aluminium and glass. While glass, the largest mass component of a PV module (making up 70% of its weight), is often recovered, it is typically of poor quality, contaminated with other materials, and can only be used for low value applications such as insulation. The challenge for the PV industry, therefore, is clear: how can we recover these materials at a high enough quality to make them useful for manufacturing new PV systems?This is where the APOLLO project enters the picture. One of the critical breakthroughs in the APOLLO project lies in improving the sorting of PV waste. Ultimately, the goal of the APOLLO consortium is to recover 93% of the materials by mass from legacy and future PV modules, making them suitable for reuse in new products. Traditional recycling has not focused on the pre-sorting phase, resulting in mixed materials and low-value outputs. APOLLO aims to address this by developing a system that categorizes glass by its specifications early in the recycling process, ensuring it can be reused in high value applications such as new solar glass or even architectural glass.

A key innovation of the APOLLO project is its advanced extraction process for recycling valuable materials from PV waste. Traditional recycling methods rely primarily on physical separation techniques, which are often ineffective in recovering high-value elements like silver, copper, and lead. APOLLO is developing a new method that combines ultrasound technology with low-impact, environmentally friendly chemical processes. This approach is designed to efficiently and cost-effectively extract and separate these materials, minimizing environmental impact and significantly increasing the economic value recovered from PV waste.

Once these materials are extracted, the next step is refining them to a level of purity suitable for use in new products. Currently, the recovered silicon from PV waste is contaminated and cannot be used directly to manufacture new solar cells. APOLLO’s solution involves refining the silicon through innovative gas phase purification processes to remove contaminants like boron and phosphorus.

The refining process, which has already been successfully demonstrated at the lab scale, results in significantly lower environmental impacts compared to the production of virgin silicon. This breakthrough offers a promising pathway for incorporating recycled silicon into new solar modules, reducing the reliance on raw materials and cutting the carbon footprint of PV production.

The final step in the APOLLO project is the development of a digital platform that will track the lifecycle of PV modules through the use of Digital Product Passports (DPPs). These DPPs will provide a trusted and transparent system for tracing the materials in PV waste streams, ensuring that they can be safely and efficiently reused. It will help create a circular economy for the PV sector, enabling more efficient recycling, reducing waste, and ensuring that valuable materials are recovered and reused.

Looking ahead, the need for effective PV recycling solutions will only grow as more solar panels reach their end of life. The APOLLO project is not only addressing the immediate challenges of recycling legacy PV systems but is also preparing the industry for the challenges posed by the next generation of solar technologies, such as perovskite-based PV panels.

About APOLLO project

The APOLLO research has been made possible by being co-funded by the European Union under Grant Agreement No. 101122277, the State Secretariat for Education, Research and Innovation (SERI), and UK Research and Innovation (UKRI). Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or CINEA. Neither the European Union nor the granting authority can be held responsible for them.

Duration: January 2024 – December 2026

Website: www.apolloproject.eu

Coordinator: FRAUNHOFER GESELLSCHAFT ZUR FORDERUNG DER ANGEWANDTEN FORSCHUNG EV

Project funded by: