CarboDoH2 is a Horizon Europe project focused on developing novel composite electrodes to accelerate hydrogen production in water electrolysis cells.

The project explores the potential of innovative low-dimensional nanomaterials, such as graphene and its derivatives, as efficient and cost-effective solutions for sustainable hydrogen generation. Coordinated by the University of Barcelona (Spain), the project also involves the Foundation for Research and Technology – Hellas (FORTH) in Greece. Running from September 2023 to August 2025, the project will span 24 months.

Background and conceptualisation:

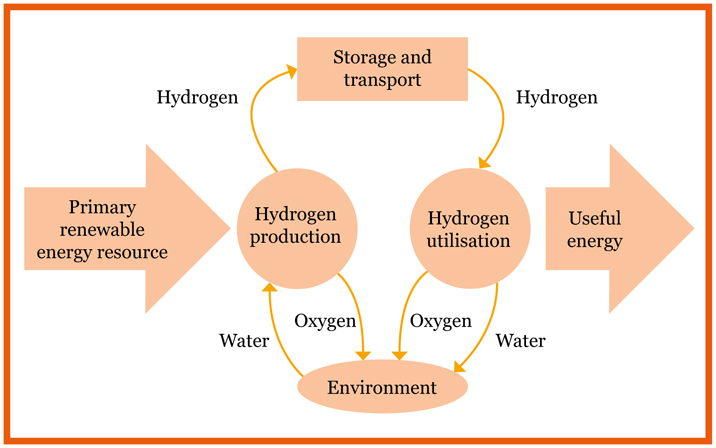

In the fight against climate change, the development of environmentally sustainable energy generation and storage technologies is essential for ensuring both environmental and economic security. As fossil fuels are finite, there is a growing need for alternative and renewable energy carriers. Hydrogen has gained considerable attention as a promising solution because it is the most abundant element in the universe and offers the highest specific energy density of any known fuel (~120-142 MJ/kg, corresponding values for petroleum and natural gas are ~45 and ~55 MJ/Kg, respectively). Additionally, hydrogen is a clean fuel: when used in a fuel cell, it produces only water, electricity, and heat. As such, hydrogen fuel cells are central to the transition towards sustainable energy systems and circular economies (see Figure 1).

Figure 1: Hydrogen life cycle derived from renewable energy

Currently, hydrogen (H₂) is primarily produced through two methods: i) natural gas steam reforming and ii) methanol reforming. However, the first method relies on a non-renewable energy source, while methane reforming results in CO₂ emissions, contributing to the greenhouse effect. As such, these conventional routes are insufficient for meeting the energy demands of a post-fossil-fuel society, while preventing global warming. An environmentally responsible, carbon-free alternative is water splitting through electrolysis, a technique for hydrogen production that does not rely on fossil fuels. Water splitting occurs in an electrolysis cell and requires a minimum potential difference of 1.23 volts to drive the reaction. In practice, however, higher potential values are required to initiate these reactions due to sluggish reaction kinetics and other inefficiencies. The hydrogen evolution reaction (HER) and oxygen evolution reaction (OER) take place at the cathode and anode of the cell, respectively, producing gaseous hydrogen and oxygen. Heterogeneous electrocatalysis plays a critical role in accelerating the electrochemical reactions on the surface of catalyst materials, enabling them to initiate at lower potentials and higher rates. Therefore, the design and development of highly efficient catalysts is fundamental for improving the overall performance and cost-effectiveness of water electrolysis for hydrogen production.

To date, noble metals from the platinum group (e.g., Rh, Pt, Ru) are the most efficient electrocatalysts for hydrogen generation. However, the high cost and scarcity of these materials limit their widespread use. In contrast, earthabundant transition metals (TMs) have also shown significant potential for HER. Among them, transition metal carbides (TMCs) are particularly promising due to their excellent performance and availability. To enhance hydrogen production per electrode surface area, it is critical to engineer catalysts with a high active surface area, thereby increasing the number of active sites. This principle lies at the heart of the CarboDoH2 project, which aims to design novel nanostructured TMCs capable of accelerating the hydrogen evolution reaction. To achieve this, we propose a new synthetic approach that enables the fabrication of nanoengineered TMC films supported by graphene-based conductive templates. These templates not only provide excellent electrical conductivity but also significantly increase the active surface area of the catalysts.

Main results:

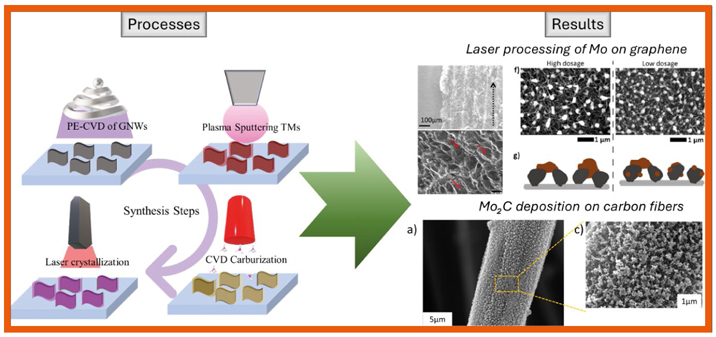

The project focuses on developing new technological concepts for the preparation of nanocomposites and their validation in a laboratory environment. To achieve this, vapor deposition techniques, such as magnetron sputtering and chemical vapor deposition (CVD), are employed. These techniques are widely used across various industries, from semiconductors and electronics to coatings and solar cells, offering significant scalability potential. This scalability is essential for advancing the technology readiness level (TRL) of our system and bringing it closer to meeting real-world operational demands. Additionally, complementary studies explore the use of laser irradiation as an efficient method for controlling and fine-tuning the electrical conductivity and surface properties of the materials.

Main outcome 1: Deposition of vertically aligned graphene nanowalls compound with a high surface-tovolume ratio. The graphene film is deposited in both semiconducting and metallic substrates. The film exhibits very good adhesion, as well as mechanical and chemical stability. It can be an ideal coating applied in current collectors to enhance the total surface area.

Main outcome 2: Transition metal carbides are deposited on graphene-based electrodes to form hybrid composite materials with a large number of active sites. Molybdenum and tungsten carbides have been proven to be very efficient electro-catalysts for hydrogen evolution. By careful tailoring of their morphology in the nanometre scale, these hybrid systems can offer performance levels comparable to platinum, even under harsh operation conditions.

Main outcome 3: Pulsed laser irradiation is employed for the rapid functionalization of the nanocomposites, effectively controlling both the density of defects in the graphene crystal matrix and the size of the transition metal nanoparticles deposited on it. These two parameters have proven to be crucial for optimizing the performance of the composites towards hydrogen generation. This outcome brings forward the application of laser-based methods for the enhancement of the efficiency of metal catalysts in the hydrogen evolution reaction.

Main outcome 4: The excellent performance of the composites is manifested by the following performance metrics:

- Capacity to generate a current density up to 1 A cm-2.

- Low required overpotentials, e.g. generation of 10 mA cm -2 at 80 mV.

- Stable performance during tenths of hours of operation.

- Excellent chemical and structural stability.

CarboDoH2 drives efforts towards the design and synthesis of advanced nanostructured catalysts with strong emphasis on cost-effective raw materials and scalable processes as key pillars.

Figure 2: Overview of the included processes and key results of the project

Key publications:

S. Chaitoglou, Y. Ma, R. Ospina, G. Farid, J. Serafin, R. Amade Rovira, E. Bertran-Serra ACS Appl. Nano Mater. 2024, 7, 22631−22639

S. Chaitoglou, A. Klini, N. Papakosta, Y. Ma, R. Amade, P. Loukakos, E. Bertran- Serra J. Phys. Chem. Lett. 2024, 15, 3779−3784

S. Chaitoglou, R. Ospina, Y. Ma, R. Amade, X. Vendrell, J. Rodriguez-Pereira, E. Bertran-Serra Journal of Alloys and Compounds 2024, 972,172891

CarboDoH2 has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No. 101062014.

Partners: