"Development of innovative lightweight and highly insulating energy efficient components and associated enabling materials for cost-effective retrofitting and new construction of curtain wall facades."

The EENSULATE project is a research project funded by the European Commission under the Horizon 2020 programme. It gathers 14 partners from eight different European countries (AGC Glass Europe, SAES Getters, Focchi, Universita Politecnica Delle Marche, Selena, Bergamo Tecnologie, Gmina Miejska Dzierzoniow, University College London, University of Ulster, Evonik, Tvitec, UNStudio, and Fenix TNT). The consortium is led by RINA Consulting.

The EENSULATE project is a research project funded by the European Commission under the Horizon 2020 programme. It gathers 14 partners from eight different European countries (AGC Glass Europe, SAES Getters, Focchi, Universita Politecnica Delle Marche, Selena, Bergamo Tecnologie, Gmina Miejska Dzierzoniow, University College London, University of Ulster, Evonik, Tvitec, UNStudio, and Fenix TNT). The consortium is led by RINA Consulting.

The main aim of the project is to develop an innovative lightweight (35 % weight reduction compared to the currently best performing modules), highly insulating energy efficient components. Simultaneously, it also develops associated enabling materials for cost-effective retrofitting and new construction of curtain wall façades. EENSULATE represents an ambitious project, which aims to introduce a novel unitized curtain wall system capable of meeting the market demand. It is expected to be an affordable (28 % reduction of total refurbishment costs), high performance prefabricated façade retrofitting solution with reduced weight and thickness. The objective of the project is to bring existing curtain wall buildings to "nearly zero energy" standards and reducing energy bills by at least 20 % while complying with the structural limits of the original building structure and national building codes.

EENSULATE PRODUCTS

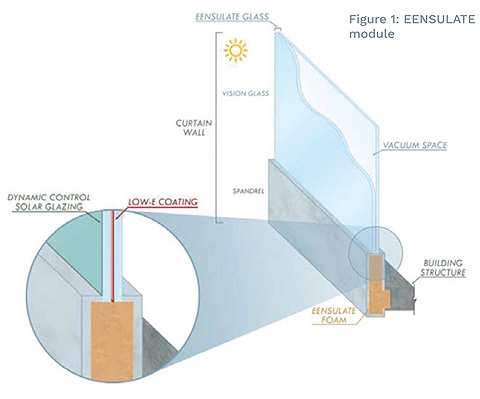

The EENSULATE project develops a module that consists of two main parts. The first one is highly insulating environmentally friendly spray foam. It allows for the cost-effective automated manufacturing and insulation of the opaque components. The curtain walls also enable significant reduction of thermal bridges during the installation process. The second product is a lightweight and thin double pane vacuum glass used for the insulation of the transparent component of curtain walls; it is manufactured through an innovative low-temperature process.

A prototype vacuum glass samples have been fabricated using seal materials. These included a hot melt type polymer and an epoxy resin. Initial trials were conducted on small scale samples to determine appropriate application, techniques and processing criteria. Consortium is currently working on the foam to improve fire resistance and higher yield. The Single Burning Item (SBI) test for three types of foam will be performed and after the test, the foam sample with the appropriate fire resistance will be used for the preliminary industrial samples.

DEMONSTRATION

Four different demo sites will be used for validation of results in different climatic conditions: Public library in Pesaro (Italy), Focchi building in Rimini (Italy), and two buildings in Dzierzonow (Poland) – School building and City museum.

EENSULATE module's main components, foam and vacuum glass, are currently under the definition of the final specifications and, in the next months, the system design of the EENSULATE module will be realized. After the system design, the first full scale prototypes will be manufactured, and the performances tests will be conducted to validate the full system. The focus will be placed on thermos-acoustic behavior and indoor comfort.

Contact information

Project ID: 723868

Website: www.eensulate.eu

Start Date: August 2016

Duration: 42 months

Project Coordinator: Daniela Reccardo

Email: daniela.reccardo@rina.org