SUSPIRE project's target is to create an effective integrated energy recovery system (equipment

& methodology) as well as a commercialization framework to save 20% of the global energy

consumption in the PRECICAST BILBAO (PCB) investment casting company.

Process industry companies require/consume a significant

amount of energy, but most of it gets lost during the

different transformation phases. To avoid this loss and to

gain efficiency, SusPIRE project's international consortium

is working on an energy recovery system which, combined

with the manufacturing process of energy intensive

companies, will recover energy from the different heat

streams increasing existing energy recovery rates.

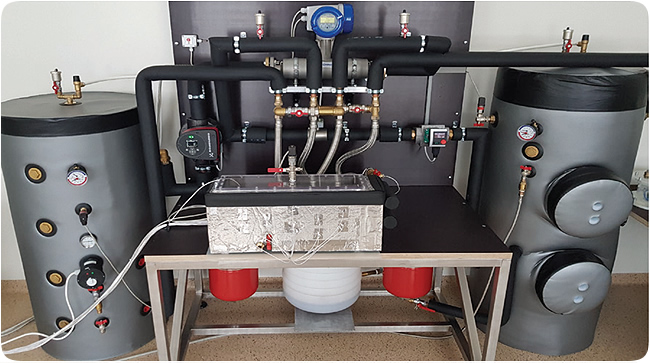

Advanced design and preliminary testing of low temperature heat exchanger for released steam in boilerclaves

Currently, a demonstrator of the project is being carried

out in the PRECICAST BILBAO (also PCB) precision casting

company (Spain), where the project consortium aims at saving 20% of the global energy consumption rates. The

results of the project will be applicable to other energy

intensive manufacturing companies at international level.

As explained by Jordi Hernando, project coordinator from

PCB "sustainability is a challenge for process industry

to gain competitiveness in a global market and develop

symbiotic capabilities with society".

During the project, by means of advanced simulation

techniques, a general architecture has been designed for

the whole plant coping with all existing types of residual

energy streams. As a result, a new generation of dual heat

exchangers with high energy recovery yield has been born.

Dual heat exchangers provide a double functionality: they

can exchange and store heat at the same time so existing

mismatches between energy generation and demand can

be encompassed.

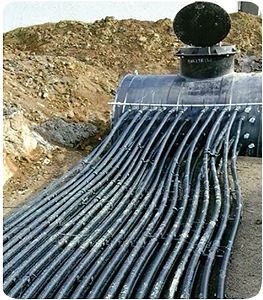

Low temperature energy recovery system supported in a Borehole Thermal Energy System and a heat pump

An innovative design and an advanced data management system to save energy

Coming to another design level, the heat exchange

equipment benefits from the latest developments in Heat

Transfer Fluids (HTF), and more specifically, in siliconbased

fluids. Syltherm 800, commercialized by DOW,

that can withstand temperatures up to 450˚C without

significant degradation, is an example of this product

category.

Also, Phase Change Materials (PCM) have been used

during the project for energy storage at two temperature

levels. For high temperature values, H190 inorganic PCM

has been applied (approximately 190˚C melting point)

while RT82 organic PCM is used for lower temperatures

(approximately 80˚C melting point).

Finally, a Borehole Thermal Energy Storage System

(BTES) has been built up in the plant. This equipment

has the specific support of a heat pump and gathers all

the low temperature residual heat streams coming from

refrigeration units of different equipment (compressors,

induction furnaces and cooling systems) and the incascade

residual heat coming from the high temperature

energy recovery circuit.

Among the main achievements reached up to date, an

advanced data management system that encompasses

optimal manufacturing and energy consumption has

been created to make a more efficient use of energy.

As explained by Fernando Santos, researcher at IK4-

AZTERLAN and technical coordinator of the SUSPIRE

project, "we have created a software to control the key

variables and key indicators that allow us to achieve the

best results in energy efficiency without disturbing the

manufacturing process or affecting product quality".

The energy stored at 190˚C is used for wax melting and

steam generation for etching baths and remaining energy

is stored in the ground whereas energy stored at 80ºC is

used for retro heating of water going into a boilerclave.

The low temperature energy supplied by the BTES is used

for building heating and hot water for workers. For the

remaining excess of heat a contract will be subscribed

with local authorities to supply heat to the sports center

next to the factory.

SUSPIRE project is funded by European Union's H2020 program for research, technological development and demonstration under grant agreement No. 680169. H2020-EE-2014-2015/H2020-EE-2015-1-PPP.