The TAKE-OFF project

In 2017, European aviation contributed 163 million tonnes of CO2, about 3.6% of Europe’s total, with a projected 21% increase to 198 Mt by 2040, making it crucial to reduce its CO2 and other greenhouse gas emissions.

Sustainable aviation fuel (SAF) from renewable sources can significantly lower the carbon footprint compared to fossil-based aviation fuels. Launched in 2021, the Europeanfunded project TAKE-OFF–Production of Synthetic Renewable Aviation Fuel from CO2 and H2 — is developing next-generation technology to produce SAF from CO2 and H2. TAKEOFF is an industrially driven project that will be a game-changer in the cost-effective production of SAF.

Conceptual models and benchmarking

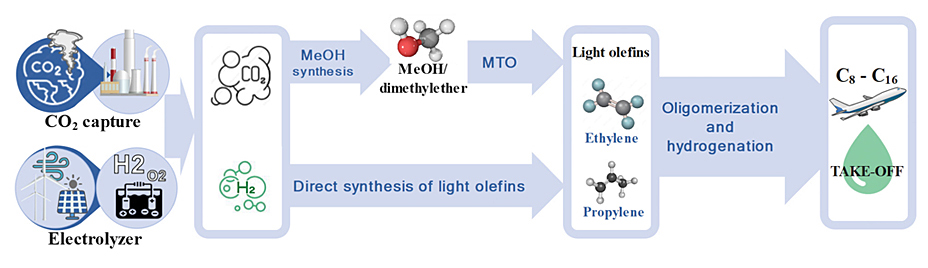

Currently, Fischer-Tropsch (FT), a certified method for producing SAF, is considered a benchmark for TAKE-OFF. Both TAKE-OFF and FT are competitive pathways for largescale SAF production using similar feedstocks. TAKE-OFF's technology involves two process lines (Figure 1):

- Line 1: Captured CO2 and H2 are first converted to Methanol (MeOH)/ dimethyl ether (DME), then to light olefins, reflecting the current state-of-the-art technology.

- Line 2: Directly converts H2 and CO2 to light olefins with process improvements from TAKE-OFF's research.

Both lines convert light olefins to jet fuel through oligomerization and hydrogenation. In the FT pathway, feedstocks are converted to syngas via reverse gas shift and then to syncrude, with final fuels influenced by catalysts, conditions, and refinery processes.

Figure 1: Overview of direct and indirect pathways development in TAKE-OFF; MTO: Methanol to olefin; MeOH: Methanol

Techno-economic and environmental assessment of jet fuels

The TAKE-OFF pathways for producing SAF from CO2 and H2 are currently at a low technology readiness level (TRL~3-4) and are expected to reach TRL 5 by the project's end. To include sustainability aspects in the early stages of design and production, all three technology lines are assessed in terms of sustainability using Life Cycle Assessment (LCA) and Technoeconomic Analysis (TEA). Multiple scenarios in terms of carbon capture, hydrogen production technology, energy sources, etc. are developed and system models for each scenario are created and simulated using experimental data (Figure 2).

Figure 2: Developed scenarios under TAKE-OFF Direct, TAKE-OFF Indirect, and FT pathways; CC: Carbon capture; WEL: Water electrolyzer; AWEL: Alkaline water electrolyzer; SOWEL: Solid oxide water electrolyzer; DAC: Direct air capture; SSP: Shared socio-economic pathways; RCP: Representative concentration pathway.

LCA results explored in this project can be used for decision-making purposes, determining whether large-scale SAF production via olefin pathways (direct and/or indirect) should be prioritized over FT pathways in the medium to long term.

The sustainability assessment is enhanced by using IPCC’s Shared Socio-economic Pathways (SSPs) to ensure sustainability goals will be reached regardless of future socioeconomic changes.

This approach considers future changes, policy implications, and socio-economic aspects. Additionally, our LCA assessment evaluates environmental impacts under three climate scenarios: the base scenario, RCP2.6, and RCP1.9. This comprehensive framework ensures a robust comparison of the sustainability of SAF production pathways.

TEA integrates technical evaluation and economic analysis to assess a technology’s economic viability. It has two primary stages: process design and economic analysis. Process design evaluates plant components, efficiencies, chemical consumption, utilities, mass and energy flow, plant capacity, and products are assessed. Economic analysis investigates capital expenditure, fixed and variable operating expenses, loan interest, salvage value, selling price, payback period, return on investment, gross profit, and net present value.