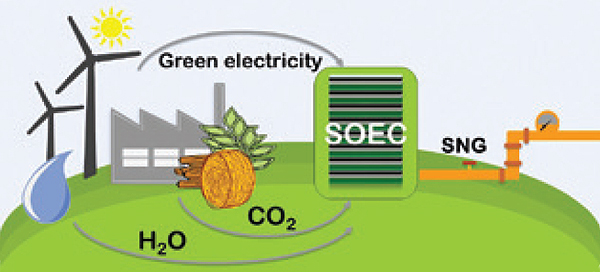

As electricity production from renewable sources such as solar and wind increases, the need for efficient energy storage and transportation concepts that can bridge the gap between production and consumption patterns become increasingly pressing.

The FCH-JU funded project ECo is currently developing and validating one such highly efficient technology, Electrolysis through Solid oxide cells (SOEC). This electrolysis technology has the ability to split water and CO2 using electricity with exceptionally high efficiencies (approaching 100%) in a process called co-electrolysis. The resulting gas mixture can then be converted into synthetic natural gas (SNG) or other compounds through standard catalytic processes.

SNG is an attractive large-scale storage medium. An extensive natural gas distribution network and spacious storage tanks already exist in Europe, which can accommodate as much as 50% of the present electricity production from renewable sources in the form of SNG without costly investments in new infrastructure. However, SOEC technology is still too expensive – the lifetime and cost have to be improved. The overall goal of the ECo project is to prolong lifetime of SOECs and to progress the technology. A comprehensive study of co-electrolysis under realistic operating conditions, such as dynamic electricity input and high pressure operation, was carried out. Based on the results, improved SOECs were developed through electrode optimization aided by advanced electro-chemical and microstructural methodology. These improvements allow for decreasing the operating temperature of the SOEC by 50-100˚C while keeping the same performance. The lower operation temperature means lower degradation and increased lifetime, as well as cheaper balance-of-plant components making the technology more economically viable.

The above activities were complemented by a design study of an SOEC plant. Using this platform it was possible to identify a range of optimum operating parameters maximising overall efficiency and the yield of the SNG production. These parameters can then serve as a guide for the development and testing of improved SOECs. Another important activity of the ECo project was to demonstrate the claimed environmental benefits for specific applications using a life-cycle analysis.

Those are mainly governed by the nature of the electricity input into the SOEC. Indeed, with a large share of electricity from renewable sources, environmental parameters, for example the reduction of the global warming potential, are positively affected by the integration of SOEC into existing industrial processes. This was shown for such diverse examples as (i) use of CO2 flue gas and heat from cement production to reduce fossil carbon input, (ii) use of process heat and excess CO2 from biomass gasification for additional SNG production, and (iii) boost of methane yield by converting CO2 to methane during biogas production.

"This project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking under grant agreement No. 699892. This Joint Undertaking receives support from the European Union’s Horizon 2020 research and innovation program and Hydrogen Europe and Hydrogen Europe Research."

For further information please contact:

Project Coordinator:

Prof. Dr. Dr. Anke Hagen,

Technical University of Denmark

Department of Energy Conversion and Storage Frederiksborgvej 399, DK-4000 Roskilde, Denmark

Phone: +45 46775884

Email: anke@dtu.dk

Website: www.eco-soec-project