Photovoltaic thermal (PVT) collectors are a novel renewable energy technology that combine the capabilities of solar thermal collectors with PV cells. Converting solar light into both electrical and thermal energy therefore collects more solar energy per surface area1.

Much research has been carried out on such hybrid technology and analysing the effect of different designs on the overall efficiency. However, cell cracking caused by thermal expansion remains a critical issue, which results in lower collector efficiency and can reduce output power performance by 10%2.

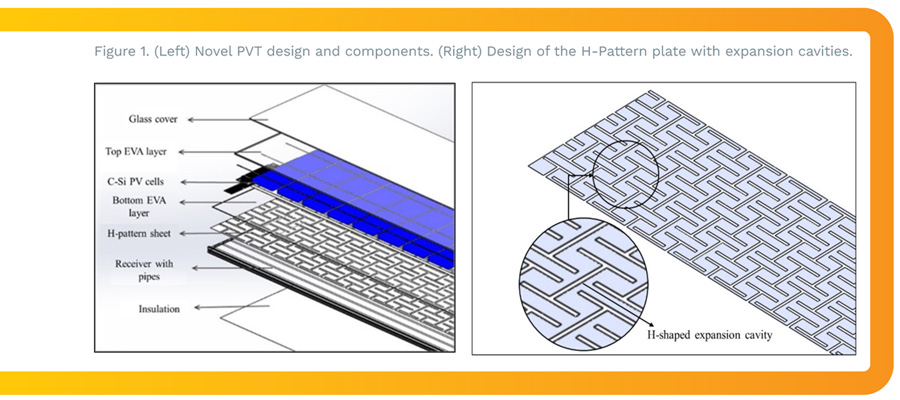

One solution could be to include an aluminium structure between the PV cells and the absorber with a design pattern that can reduce the risk of cell cracking. The approach developed under the EU-funded RES4BUILD project proposes a novel PVT design that decreases thermal stress on the cells. This novel design is called H-Pattern, with an expansion cavity pattern in the shape of the letter 'H' (Figure 1).

The design allows for thermal expansion in all directions by expanding into its own cavities. This creates a smaller total expansion in any single direction, which in turn is expected to drastically diminish the risk of cell cracking. While the use of metals in thermal applications can bring problems of higher thermal expansion, these can be addressed by the expansion cavities of the H-pattern.

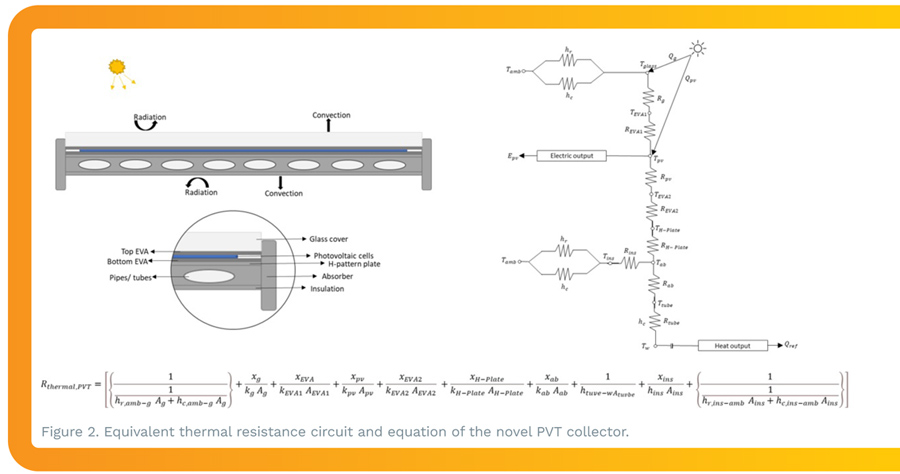

The thermal expansion of the H-pattern plate and other components were evaluated separately and as a whole due to temperature variations in different dimensions. This is particularly important when different materials are considered. The proposed PVT collector was modelled, and the results validated against experimentally derived performance curves. Multiple modes of heat transfer occur in the different layers of a PVT collector (Figure 2). Heat transfer to and from the collector will affect the temperatures attained in the various layers as well as the heat transfer fluid flowing through the pipes3. These were all carefully investigated.4

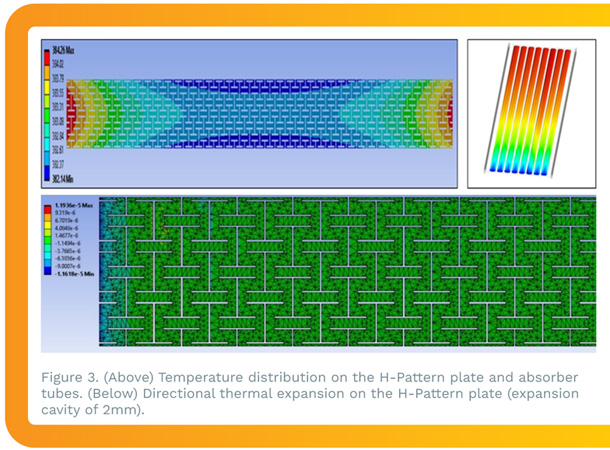

The proposed novel PVT collector, with its optimal balance of performance, cost, and ease of manufacture, has the potential to achieve optimal use of solar energy. The expansion cavities help improve the performance by reducing heat loss and thermal expansion (Figure 3). The proposed H-Pattern with cavities dimension of 2mm helps to reduce thermal expansion by almost 58% in comparison to a standard PVT collector. It can also reduce heat loss by 5%.

Work is ongoing to demonstrate and complete the novel PVT collector. This technology has been developed together with the integrated energy system pilots that are being tested in Denmark and Greece in the RES4BUILD project. Along with a co-design process involving stakeholders, a rigorous life cycle assessment and business analysis, the project hopes to pave the route to market, contributing to the decarbonisation of energy consumption in buildings.

This project has received funding from the European Union's Horizon 2020 research and innovation programme under Grant Agreement No. 814865 (RES4BUILD). This output reflects only the author's view. The European Climate, Infrastructure and Environment Executive Agency (CINEA) and the European Commission cannot be held responsible for any use that may be made of the information contained therein.

1. V.M. Patel, H.A. Patel, Design and Development of Solar PVT System, International Journal of Engineering Research & Technology (IJERT), 1 (2018).

2. M. Dhimish, V. Holmes, B. Mehrdadi, M. Dales, The impact of cracks on photovoltaic power performance, Journal of Science: Advanced Materials and Devices. 2 (2017) 199–209.

3. M. Kaviany, A.M. Kanury, Principles of heat transfer, Appl. Mech. Rev. 55 (2002) B100–B102.v 4 E. Yandri, Modeling Joule

4. E. Yandri, Modeling Joule Heating Effect on Thermal Efficiency of Photovoltaic Thermal (PVT) Collectors with Operation Mode Factor (OMF), Applied Sciences. 12 (2022) 742.